Boeing told that workers have finally joined the nose section of the 787 to the forward fuselage, but a spokeswoman admitted the two composite fuselage barrels were not a seamless fit and the solution proved “challenging.”

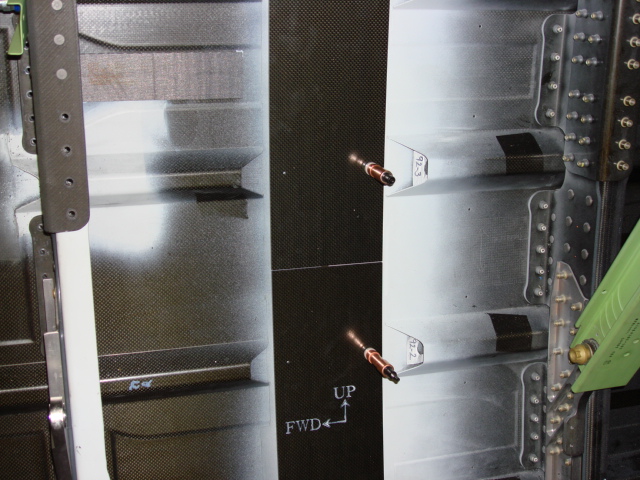

A Everett factory source told there were unexpected problems in trying to join fuselage sections and that loads had to be applied by engineers to finally connect the forward and nose sections. This required that some internal structure installed before the sections arrived in Everett be removed to make the massive one-piece composite barrels less rigid, the source said.

This also added to the growing work load that Boeing faces in order to meet the July 8 rollout date.

Boeing engineers calculated the amount of hydraulic load that could be safely applied to the structures to force the sections to fit, the source said.

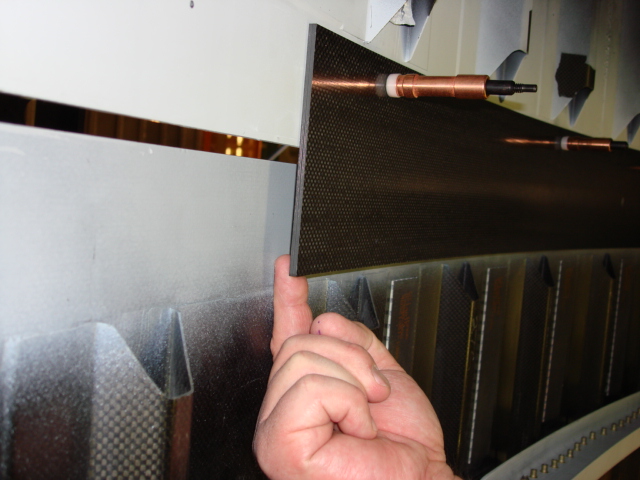

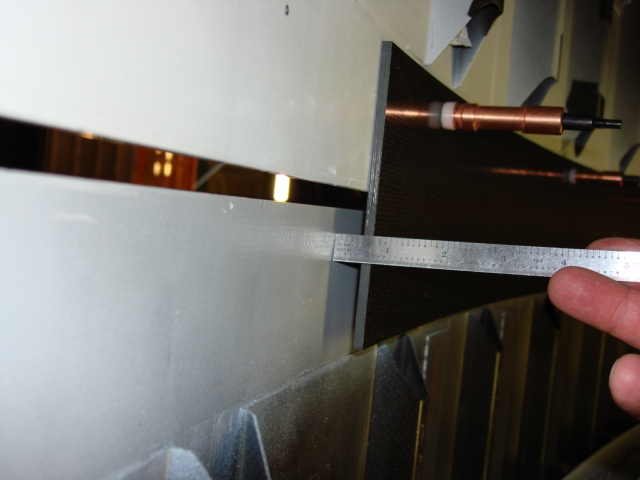

The problem was on the left side of section 41 – the nose and cockpit – manufactured by Spirit AeroSystems in Wichita. A bulge of more than an inch and a half was discovered when that section was initially lined up in tooling to be connected with the forward fuselage section 43, manufactured by Kawasaki in Japan, the source said.

Section 41 arrives from Wichita as one piece. Section 43 is connected in Charleston, S.C., with mid fuselage sections 46 and 44 that are manufactured by Alenia in Italy. That entire fuselage structure is flown to Everett for final assembly. (Seattle Times)

Photos of the 787 Fuselage Gaps

Heard something about this story?: http://jacno.com/za-an-inmo.htm

I spent more than 25 years of my life in the aircraft manufacturing industry machining & programming these very complex aircraft parts.

The top 20 executives who are making the decisions on the future of this company BAC have no concept of the risk they have exposed this one of a kind company to, for a cost savings of a few hundred million dollars.

Not one of these top dollar yahoo’s have ever spent a hour in a manufacturing environment to develop any respect for the man hours needed to develop the skill sets needed to make a plane fly.

When it is all over they will be gone but the mess they have created with their high hopes to replicate what McDonalds & KFC have proven to work world wide will almost destroy this American made top shelf Aircraft Product.

The hope of wall street to place this company into the hands of unskilled managers will be as the Wall Street Journal once said ( not down sizing / but / dumb sizing )

A complete failure to understand the real value of skilled labor & take it out side of a company’s legacy of complete control of the very best quality is a real miss que .

This with the hope of saving a few bucks, they take this risk of demolishing the hard earned respect of the world.

William Boeing had hand’s on experience, Henry Ford knew the value of every employee on his payroll, knew every job, it’s importance & sought to pay top wages.

Corporate America has looted every thing they have touched & ruined our ability to lead with pride in their quest to save a few bucks.

This time it will be one real mess to clean up, I hope this will end this madness of disrespect of the American workers value, of the skilled labor required to make a plane fly.

It is long over due to fire these pen pushers with no skills at all!

Who can’t fight their way out of a paper bag.

The ones who have dismantled our ability to lead the world!

By not allowing us to continue to manufacture the best products ever made.

They have outsourced our sovereign capacity to self defense.

I agree with everything you have said, I was unfortunate enough to work for Boeing in Australia it ended badly when I found out that Boeing regarded lying as a legitimate quality control tool, 95% of the employees I meet had no idea of the forces that would be inflicted on whatever part they were manufacturing therefore they were incapable of detecting the most basic of problems, notches scratches and a myriad of other stress risers were being built into almost every structure, as often as not when I indicated defects the answer was “ NOTHING A BIT OF PAINT WONT FIX†or words to that effect, gone are the days of the dedicated trained aircraft airframe operator ( airframe fitter ) if you pay peanuts you get monkeys.

Talking about monkeys, it looks to me that the Boeing engineers have got BIG problems on their hands because they forgot one of the basics of aircraft construction, Temperature, I bet you London to a brick they did not pay enough attention to the local temperature at each contractors plant, if the fuselage barrel is manufactured in Japan and the nose section in Wichita it’s quite feasible that the site temperature differential will cause a mis-match and if they have one mis-match there must be 100s,

I ran into this very problem in the 1970s in Israel, we were building the nose section of the IAI Arava in Tel-Aviv and the fuselage barrel was being manufactured in Ber-Sheba, when the sections came together in Tel-Aviv they did not fit, we solved the problem by running the mains water through the jigs at both locations this maintained the jig’s in both locations at about 14c, the Arava was a small twin engined military aircraft with a fuselage 3mt in diameter and we had problems when the temperature differential was 5-7c blow that up to the size of a 787 and it’s easy to lose or gain an inch or two.

Theres a lot to be said for building all of an aircraft in one location Boeing used to know that and why looks like they lost the plot

The B-2 Bomber is made of the same material, Boeing built sections for Northrop and similar

problems were encountered. The B-2 could have been made out of pure gold cheaper than

each aircraft cost the taxpayer. Composites are great for Corvettes, baseball bats, hard hats,

but with the current people running Boeing I doubt if this plane will ever fly and if it does

what will be the long term effects of pressurization and decompression on the composite materials

and temperature extremes….do you really want to get aboard this plastic model in the sky????

It appears that Boeing is using fasteners in the primary composite fuselage structure to secure sections of the fuselage together. Won’t this eventually result in stress concentrations where the holes have been made in the graphite composite structure–resulting in possible future structural failure?

Why are they not bonding the components together?

Isn’t this also an issue of hiring an inexperienced/dumbed down workforce as well as un-technical managers, who only think about (A) Speed and (B) Money – Rather than true “thinking” craftsmanship! Hiring people just to fill quota’s is crazy (and FYI I’m not white, so let not go down the PC blah.. blah.. blah.. route!) – They should hire the BEST Period – Rather than some cosmopolitan workforce! The BEST! I’ve got friends and family who have worked at Boeing/with Boeing and I can tell you some of the “Non-Managers” (regular workers) are also not greatly skilled, and lack experience/quality in workmanship.

You just simply need to look at American Manufacturing (including Boeing) in the 1950s/60s & 70s and look at the technical achievements gained then, and consider America LED the world manufacturing just 30 years ago! What’s happened since then!

It appears the true Pinnacle of American Manufacturing & Technology/Enterprise was the 1950s > Mid-70’s. Sadly after that it was all down hill from there, as they sold their soles and great companies to Wall street (Just do Google Search on who really owns/runs Wall Street and America, you’d be Surprised many are NOT Americans)! – Who only cares about $$$$ and nothing about Quality/Craftsmanship!

This madness of purely $$$$ has got to end, *nothing lasts forever*. America was a great country a mere generation ago, sadly its swiftly becoming a basket case (2009 Crash)! Was a Depression, people who STILL this we are in a “Recession” have got to be kidding themselves!! We are heading towards a Giant Brazil Status = (small rich elite) / tiny and fractured Middle Class and a MASSIVE Working Poor/Underclass.

I hope to god the above scenario NEVER happens! As you guys should know ANY Successful & Stable Country, should/must have a very sizable Middle Class. Sadly America’s Middle class and much of the Western Worlds Middle Class, is under-attack by MANY of the Elites/Wall Street Types, who in my opinion seriously want a DUMBED Down and Subservient Population READ = “Controlled Citizen” = I am not mad, just look at America & Increasingly Europe since 2001 (9/11) – We are LOOSING our true freedoms, and independence. I bet you the founding fathers must be turning and wheeping in their graves, seeing whats happening to their once great and strong country :o(

Like I said People need to Wake up!! Google “who runs America and Wall Street” – God willing these scoundrals will FAIL – Like I said Nothing last forever just hope America/Europe & the world figure it out in time, and before irreparable damage is done!!

Thanks